Company slogan:

Wedge wire screen,water well screen,stainless steel filter nozzle,v wire screen, screen nozzle,screen plate, flat wedge wire panel, wire wrapped screen, screen pipe, screen tube, oil well screen, filter element,rotary drum screen,lateral screen arms,strainer nozzle, johnson wire screen, sieve bend screen, wedge wire grating, support grids, double loop wire ties, etc

OEM Overview:

Title: OEM/ODM Services for Wedge Wire Screens at Anping County Xinlu Wire Mesh Products Co., Ltd

-

Understanding OEM and ODM: Before delving into the services, let's clarify the concepts of OEM and ODM. OEM (Original Equipment Manufacturer) refers to the production of customized products based on a client's specifications, while ODM (Original Design Manufacturer) involves the design and development of innovative products according to market demands.

-

OEM Services for Wedge Wire Screens: Under our OEM services, we collaborate closely with clients to manufacture wedge wire screens tailored to their specific requirements. Our team of experts utilizes advanced production techniques and state-of-the-art machinery to create products that align with the client's design and specifications.

-

ODM Services for Wedge Wire Screens: Our ODM services focus on designing and developing wedge wire screens that stand out in the market. With a dedicated research and development team, we stay updated with the latest industry trends and technological advancements to create innovative and competitive products.

-

Streamlined Process: To ensure a smooth and efficient process, we follow a well-defined workflow for our OEM/ODM services:

4.1 Requirement Confirmation: We engage in detailed discussions with clients to understand their specific needs, including dimensions, shapes, materials, surface treatments, and any other requirements they may have.

4.2 Design and Development: Based on the client's requirements, our experienced team of designers and engineers work collaboratively to create customized designs and develop prototypes.

4.3 Sample Production: Once the design and development phase is complete, we produce samples for client evaluation and approval. This stage allows clients to provide feedback and suggest any modifications or improvements.

4.4 Manufacturing and Production: Upon receiving the client's approval, we proceed with the full-scale manufacturing and production of the wedge wire screens. Our skilled workforce ensures adherence to the client's requirements and maintains the highest quality standards.

4.5 Quality Control: We implement stringent quality control measures throughout the manufacturing process. Our quality assurance team conducts thorough inspections and tests to ensure that the wedge wire screens meet the design specifications and client expectations.

4.6 Packaging and Delivery: After passing the quality control checks, the wedge wire screens are carefully packaged and prepared for delivery. We work closely with the client to determine the most suitable transportation method and ensure timely delivery.

Anping County Xinlu Wire Mesh Products Co., Ltd offers comprehensive OEM/ODM services for wedge wire screens. With a streamlined process, a dedicated team of experts, and adherence to Google's latest algorithm rules, we strive to provide customized solutions that meet the unique requirements of our clients. Partner with us to experience exceptional quality and customer satisfaction

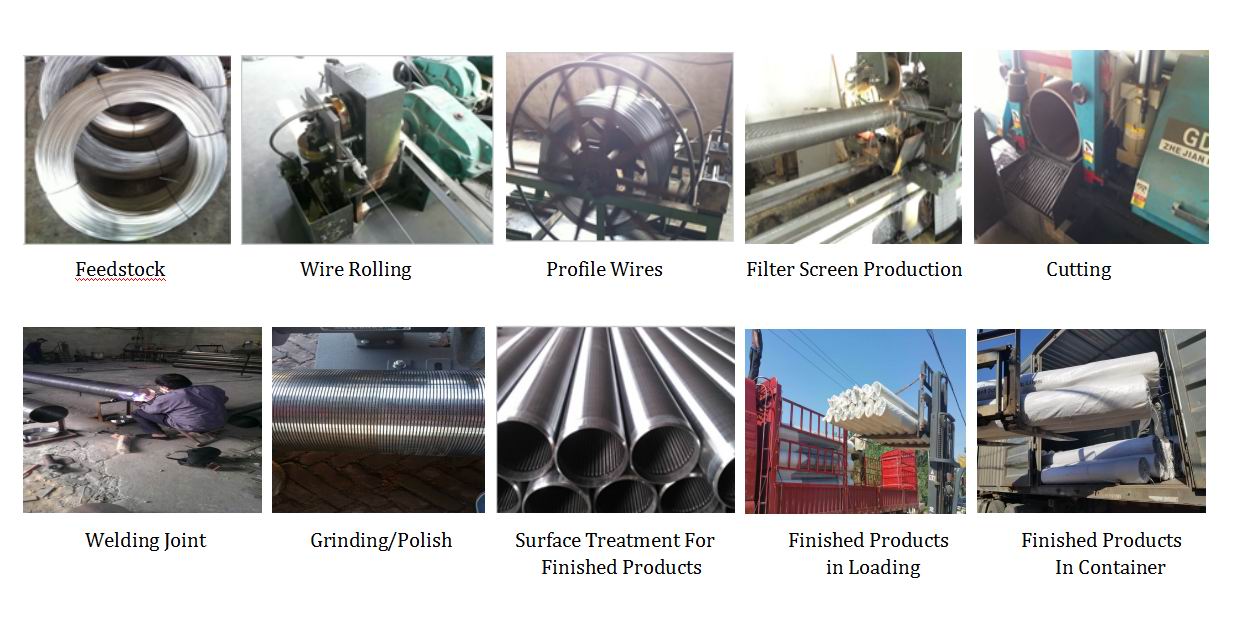

Production Line:

Anping County Xinlu Wire Mesh Products Co., Ltd - Wedge Wire Screen Production Process

Our factory follows industry best practices and employs advanced techniques to ensure the highest quality standards and customer satisfaction.

-

Material Selection and Preparation: At Xinlu Wire Mesh, we carefully select high-quality materials, primarily stainless steel or other corrosion-resistant alloys, for wedge wire screen production.

-

Wire rolling: According to customer needs, through the wire rolling machine repeatedly rolled into the size of customer needs. Common sizes 1.5x2mm, 2x3mm, 2.5x4mm, 3x4.6mm, 3x6mm, 3.8mm, etcThe chosen materials are then prepared by cutting them into appropriate sizes and shapes.

-

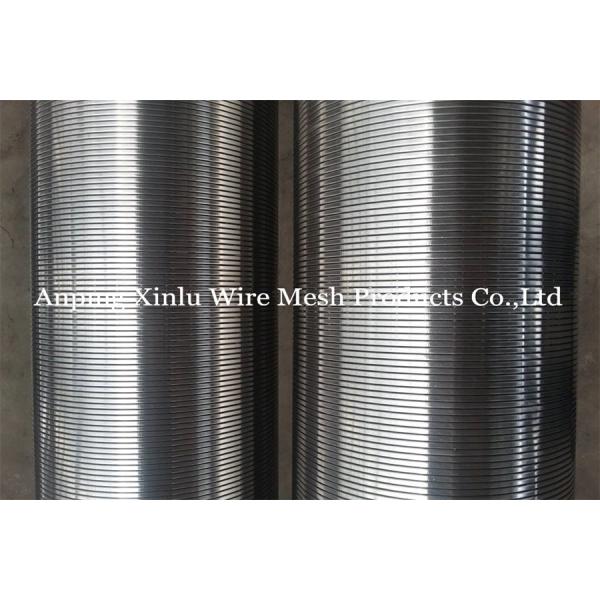

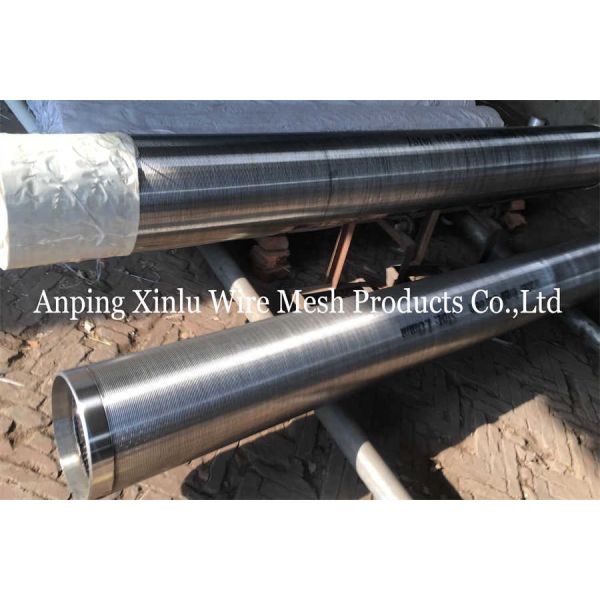

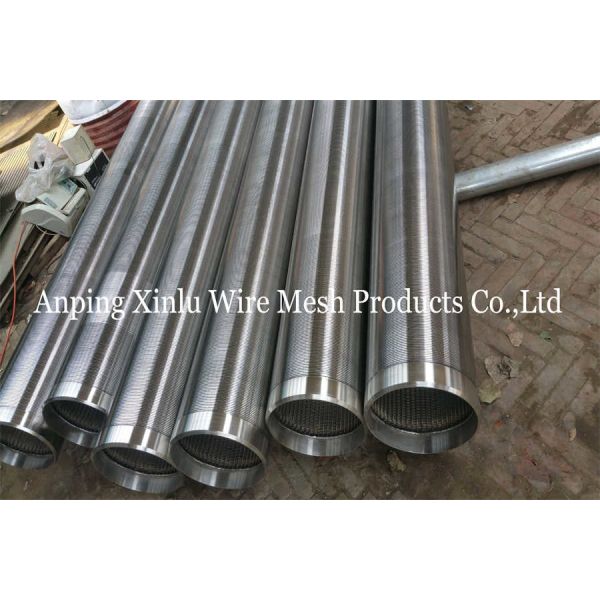

Wire Wrapped Welded Screen Mesh Machine : Use wire winding screen machine to produce different lengths of screen pipe /screen tube or cylinder sccreen according to customer size. Common screen pipe size 2 "3" 4 "6-5/8", 8, 9-5/8-5/8, 10-3/4 ", 12-3/4 "14" 16 "and so on, common 3 m and 6 m length

cylinder sceen diameter up to 2 meters

-

Welding: The prepared materials undergo welding using advanced techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. This process ensures the strong and secure connection of the materials, creating a unified structure with reliable and leak-proof welds.

-

Forming: After welding, the materials are shaped to create the desired wedge wire screen structure. This can be achieved through processes like rolling or stretching. Rolling involves extruding the materials through rollers to form the wedge-shaped profile, while stretching involves elongating the materials to the required shape.

-

Processing: The formed wedge wire screens undergo various processing steps to refine their edges, perforate them with precise holes, and achieve the desired dimensions. Additionally, the screens are carefully cut and polished to enhance their surface smoothness and precision.

-

Surface Treatment: To meet specific requirements, the wedge wire screens may undergo surface treatments such as electroplating, coating, or polishing. These treatments provide additional corrosion resistance, aesthetic appeal, and durability to the screens.

-

Inspection and Quality Control: Xinlu Wire Mesh prioritizes quality control throughout the production process. Our dedicated team conducts rigorous inspections to ensure that the wedge wire screens meet design specifications and customer requirements. This includes dimensional measurements, weld quality assessment, surface smoothness evaluation, and corrosion resistance testing.

-

Packaging and Shipping: Once the wedge wire screens pass the quality control checks, they are carefully packaged to protect them during transportation. We utilize wooden or cardboard boxes to safeguard the screens from damage. We also ensure appropriate shipping methods and timely delivery as per customer requirements.

Anping County Xinlu Wire Mesh Products Co., Ltd follows a meticulous production process for wedge wire screens, starting from material selection and preparation, through welding, forming, processing, surface treatment, and quality control. By adhering to industry best practices and employing advanced techniques, we strive to deliver high-quality wedge wire screens that meet the expectations of our valued customers.

R&D:

Research and Development (R&D) for Wedge Wire Screens

Introduction: At Anping County Xinlu Wire Mesh Products Co., Ltd, we prioritize innovation and continuous improvement. Our Research and Development (R&D) department plays a crucial role in developing advanced wedge wire screens that meet the evolving needs of our clients. This article will highlight our R&D efforts and how they contribute to the development of high-quality wedge wire screens.

- R&D Objectives: Our R&D team is committed to achieving the following objectives:

1.1. Product Innovation: We strive to develop innovative designs and technologies for wedge wire screens, ensuring that our products stand out in the market. Our R&D engineers stay updated with the latest industry trends and conduct extensive research to identify areas for improvement and new product opportunities.

1.2. Material Selection and Enhancement: We continuously explore new materials and techniques to enhance the performance and durability of our wedge wire screens. Our R&D team conducts rigorous testing and analysis to select the most suitable materials that meet the specific requirements of our clients.

1.3. Process Optimization: Efficiency and precision are crucial in the manufacturing process. Our R&D team focuses on optimizing production techniques, streamlining processes, and implementing automation where applicable. This ensures consistent quality and reduces lead times for our wedge wire screens.

-

Collaborative Approach: We believe in the power of collaboration. Our R&D team works closely with clients, industry experts, and academic institutions to gain insights, exchange knowledge, and leverage external expertise. This collaborative approach allows us to develop cutting-edge solutions that address industry challenges and exceed client expectations.

-

-

Testing and Quality Assurance: To ensure the reliability and performance of our wedge wire screens, our R&D team conducts extensive testing and quality assurance procedures. This includes:

3.1. Performance Testing: We evaluate the mechanical strength, filtration efficiency, and other performance parameters of our wedge wire screens. This testing ensures that our products meet or exceed industry standards and client requirements.

3.2. Durability Testing: Our R&D team subjects the wedge wire screens to rigorous durability tests, simulating real-world conditions and environments. This ensures that our products can withstand the demands of various applications and maintain their performance over time.

3.3. Quality Control: We implement strict quality control measures throughout the R&D process. Our team adheres to international quality standards and guidelines to ensure that our wedge wire screens consistently meet the highest quality benchmarks.

- Continuous Improvement: Our R&D efforts are not limited to initial product development. We believe in continuous improvement and strive to enhance our wedge wire screens based on customer feedback, market trends, and technological advancements. This iterative approach allows us to stay at the forefront of the industry and deliver superior products to our clients.

Anping County Xinlu Wire Mesh Products Co., Ltd's R&D department is dedicated to innovation, product enhancement, and process optimization for wedge wire screens. Through collaborative partnerships, rigorous testing, and a commitment to continuous improvement, we ensure that our products meet the highest quality standards and exceed customer expectations. Partner with us to benefit from our cutting-edge R&D capabilities and access advanced wedge wire screens for your specific needs.

Our Team:

Title: Introduction to Anping County Xinlu Wire Mesh Products Co., Ltd - A Leading Manufacturer of Wedge Wire Screens and Related Products

Introduction: Anping County Xinlu Wire Mesh Products Co., Ltd is a renowned factory specializing in the production of high-quality wedge wire screens, water well screens, stainless steel filter nozzles, Johnson Wire Screens and sieve bend screens. With a strong commitment to innovation and customer satisfaction, our team of dedicated professionals strives to deliver top-notch products that meet the highest industry standards.

- Company Overview:

- Establishing Excellence: Our factory, Anping County Xinlu Wire Mesh Products Co.,Ltd located in Anping County, has been in operation for over 20 years, gaining a reputation for excellence in the wire mesh industry.

- Manufacturing Capacity: Equipped with state-of-the-art machinery and advanced production techniques, we have the capability to meet diverse customer requirements.

- Industry Experience: With extensive experience in the field, we have successfully served clients from various sectors, including water treatment, mining, oil and gas, and food processing.

- Expert Team:

- Seasoned Management Personnel: Our team comprises seasoned management personnel who bring years of industry experience and strategic insights to the table.

- Skilled Engineers: Our team of skilled engineers possesses in-depth knowledge of wedge wire screen manufacturing processes, ensuring the production of superior-quality products.

- Dedicated Sales Team: Our sales team is committed to providing personalized customer service, understanding clients' needs, and offering tailored solutions.

- Technological Prowess:

- Cutting-Edge Research and Development: We invest in continuous research and development to stay at the forefront of technological advancements in the wire mesh industry.

- Advanced Manufacturing Techniques: Our factory employs advanced manufacturing techniques, ensuring precision and consistency in the production of wedge wire screens and related products.

- Quality Assurance: We adhere to strict quality control measures, conducting rigorous inspections at every stage of the manufacturing process to ensure product excellence.

- Product Advantages:

- Premium Materials: We utilize high-quality stainless steel and other corrosion-resistant materials to ensure the longevity and durability of our products.

- Customization Options: Our factory offers a wide range of customization options, allowing clients to tailor the specifications of wedge wire screens and related products to their specific needs.

- Wide Applications: Our products find applications in various industries, including water treatment, mining, food processing, and architectural design.

- Client-Centric Services:

- Consultative Approach: We adopt a consultative approach, working closely with clients to understand their unique requirements and providing expert guidance throughout the project.

- Timely Delivery: We prioritize timely delivery, ensuring that clients receive their orders within the agreed-upon timeframe.

- After-Sales Support: Our dedicated customer support team is readily available to address any queries or concerns post-purchase, ensuring complete customer satisfaction.

- Industry Recognition:

- ISO 9001 Certification: We have obtained ISO 9001 certification, reflecting our commitment to maintaining the highest quality standards in our manufacturing processes.

- Positive Client Feedback: Our track record of delivering exceptional products and services has garnered positive feedback from satisfied clients, further establishing our credibility in the industry.

- Future Outlook:

- Innovation and Expansion: We are committed to continuous innovation, exploring new technologies and expanding our product portfolio to meet evolving market demands.

- Sustainable Practices: We aim to integrate sustainable practices into our manufacturing processes, contributing to environmental conservation and social responsibility.

Anping County Xinlu Wire Mesh Products Co., Ltd stands as a leading manufacturer of wedge wire screens and related products, driven by a team of experienced professionals and a commitment to excellence. With a focus on technological advancements, customization options, and exceptional customer service, we strive to be the preferred choice for clients seeking top-quality wire mesh solutions.

History:

Xinlu Wire Mesh Products Co., Ltd. is Feiya International Group Anping Branch Factory, located in Anping County, which enjoys the reputation of "Hometown of Chinese Wire Mesh", and its predecessor is Anping Wedge Wire Mesh Factory. Mainly produce wedge wire screen product series.

After several years of hard work from the first equipment in 2009, we now have five wire-wound screen equipments. The diameter can complete 99% roundness, the filter slot of the productcan reach 30 microns, the length is 6 meters, and the diameter production range is from 25.4mm to 2 meters.

Export to Ukraine, Russia, Mongolia, Iran, Pakistan, India, Japan, South Korea, Vietnam, Malaysia, Indonesia, Thailand, Colombia, Taiwan, Spain, Singapore, Costa Rica, the United States, Australia, Brazil, Germany, Mexico, Turkey, UAE,etc. all around the world.

We plan to purchase a device with a length of up to 12 meters next year. In the coming days, we will provide you with good service and good quality.

Anping County XinLu wire mesh products Co., Ltd. sincerely welcome new and old customers call advisory.

Service:

water well screen, perfect roundness screen tube, profile wire screen pipe, wedge wire screen, wire wrapped screen, screen tube, screen pipe, sand control well screen, oil well screen, v wire slot screen, rod based continuous slot screen, wire wound stainless steel screen pipe, johnson well screens

Wedge wire strainer nozzle, stainless steel filter nozzle, screen nozzle johnson type, water&gas strainer, changeable filter element, stainless steel lateral arm, lateral pipe, head lateral, wire wrapped nozzle pipe, pipe screens, water input device, resin sprayer fittings, water distributor, center distribution drainage device, water filter nozzle, single tube type valve bounet, double tube type diving helmet, Resin Traps

Flat Wedge Wire Panel, Wire wrapped panel, Johnson screen plate, sieve bend screen, arc screen plate, profile wire slot panel, v wire slot panel, v wire flat screen, wedge wire grating, wedge wire support grids, rotary drum screen, cylindrical screen

Used in:

Architecture & Construction,

Food & Beverage Screens,

Mineral & Aggregate Processing,

OEM Screen Components,

Pulp & Paper Screens,

Refining & Petrochemical,

Waste Water Treatment,

Water Well & Oil well,

Salt industry,

Coal,

Mine