(1)Good adaptability: fully considered all kinds of special requirements suggested by material and technology, optimization design is implemented to the main components of appropriability and adjust ability. As long as users explain its installation place, physical chemical properties of material processing and technological requirements before buying, we will provide the applicable model.

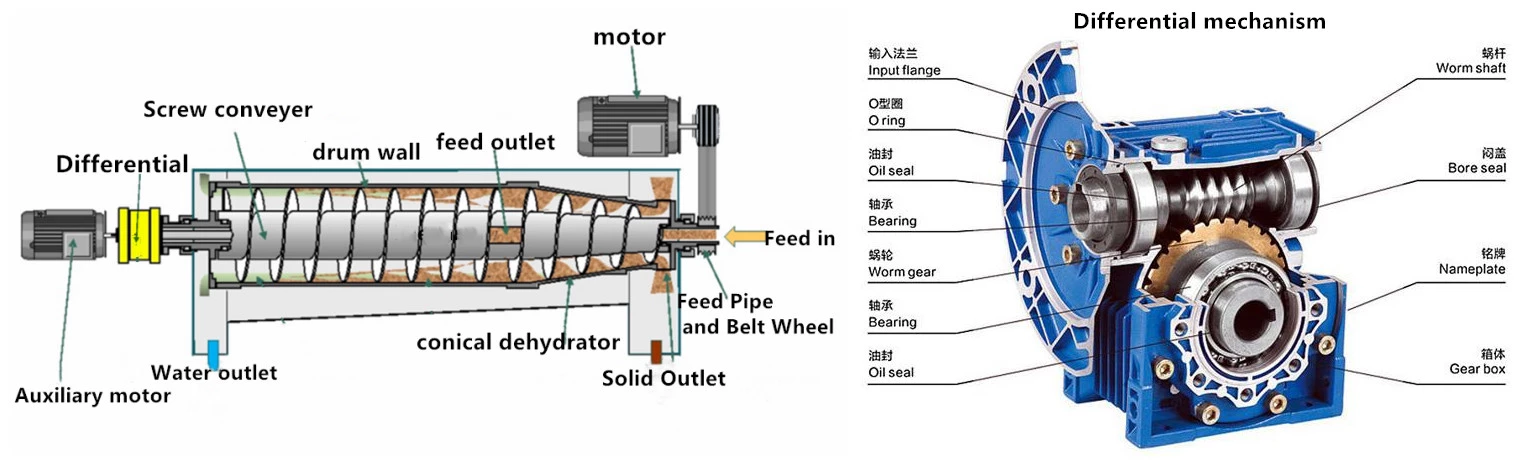

(2) High degree of automation: this machine completes feeding, separating, discharging etc. automatically while working with high speed.It realized automatic control of centrifugal separation and centrifugal washing by using programmable controller.

(3)Good operating stability: the differential using by this machine is cycloid gear differential or planet gear differential, it features large torque, extensive adjusting range etc.

(4)Good manufacturability: adopting double electrical machine and double frequency conversion energy regeneration differential rotating speed system to control, adjusting differential rotating speed flexibly and infinitely variable and regulating differential rotating speed momentarily according to the change of material.It is the real energy saving product.

(5)Good operating environment:centrifugal machine separates material under fully closed condition. That ensures operating site neat and non-pollution, and realizes the civilization production.

(6)complete and reliable safety protection device: it is equipped with torque protection, power control etc., can effectively eliminate or reduce the damage caused by sudden fault.

(7) Attractive appearance: engine base adopting high quality carbon steel to weld, and surface is smooth after special fabrication processing.It seems integral aesthetic feeling as the compact size and beautiful appearance.

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)

Language

Français

Русский язык

Español

日本語

Português

Show all machinery categories

Apparel & Textile Machinery

(75900)

Building Material Machinery

(55852)

Cleaning Equipment

(104054)

Electronics Production Machinery

(39881)

Energy & Mineral Equipment

(127869)

Engineering & Construction Machinery

(401378)

Environmental Machinery

(35590)

Food & Beverage Machinery

(97353)

Industrial Compressors & Parts

(28499)

Industrial Robots

(3603)

Industry Laser Equipment

(44115)

Machine Tool Equipment

(129643)

Machinery Accessories

(202994)

Machinery Service

(996)

Metal & Metallurgy Machinery

(69132)

Packaging Machine

(102444)

Paper Production Machinery

(29371)